Customer Technical Service

We aim to provide the best possible service for our clients. Our objective is to accompany our clients after installation, and assure them to have a partner who will take care of his machine once it is running. We deal with corrective problems and help with preventive maintenance, provide spare parts, perform revalidations and calibration, and answer all client’s questions with our expertise.

Preventive Maintenance

Preventive maintenance’s objective is to guarantee a great availability of your equipment, to allow you an optimal use, very close to its initial state during the first validation. Working together with our specialized maintenance team, you will have the insurance of having an equipment well maintained, without over servicing. The sterilization equipment is a very specific one, with a very long time cycle. When some parts are submitted to aggressive chemicals or stress, some other will work in very low duty.

Corrective Maintenance

Corrective maintenance is offered to identify, isolate, and rectify a fault so that the failed equipment can be restored to an operational condition. Sterimed engages itself to react as soon as possible, prioritising preventive maintenance clients. For failures in the control system, Sterimed provides tele-maintenance. We count with a full automation department available to solve your problems remotely, minimizing machine downtime and lowering costs since no travel fares will be needed.

Revamping

Sterilization machines can last for more than 20 years, while control systems can become obsolete in a shorter term. Sterimed believes it is important to update the sterilisation control system in order to assure a great availability of your equipment, and hence, we provided status assessment of your existing equipment and consulting for partial or complete revamping. We offer auto batch release, parametric release, new HMIs, programs, actualized reports, and new control systems.

Calibration

Instrument calibration is one of the primary processes used to maintain instrument accuracy. Sterilisation equipment needs to be calibrated yearly in order to cope with the quality norms. Sterimed offers calibration services for temperature probes, pressure sensors, gas transmitters, balances and humidity sensors. We collaborate with our partner LabCal, and we follow their practices, accredited by the American Association of Laboratory Accreditation (A2LA) and the Singapore accreditation council (SAC), compliant with the ISO 17025.

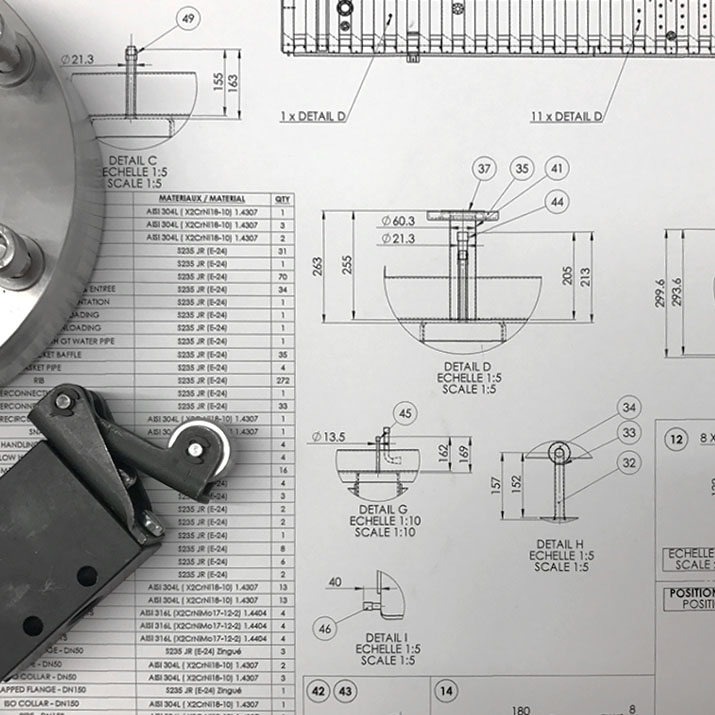

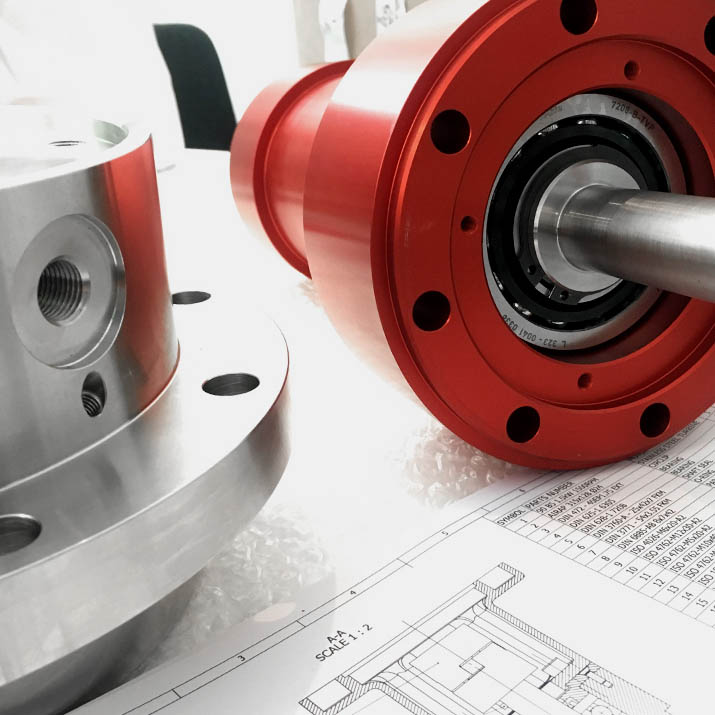

Spare Parts

Sterimed counts with a department dedicated to supply spare parts rapidly and efficiently. All spare parts are original and certified, compliant with Sterimed specifications, and guaranty for one year. All replacement parts are carefully selected among our well-recognized suppliers for medical equipment such as Busch, Endress+Hauser, Siemens, Gemu, between others. A technician is always available during our office opening hours in Switzerland to answer your questions or help you determine references.

Revalidation

Annual revalidation is compulsory to achieve the quality assessments stated in ISO 11135. Sterimed is able to perform the revalidation of your chamber to demonstrate the capability of the equipment to deliver the range of operating parameters and operating limits contained in the process specification. This range of parameters and operating limits will include the initial sterilization process that has been defined in process definition. Also, this revalidation will determine the performance of associated ancillary systems. For example, the capability of the EO vaporizer to achieve a minimum EO input temperature.